Hydraulic Pump- The Essential Salon Furniture Accessory You Can’t Ignore

Introduction

As a crucial component of salon furniture, the hydraulic pump ensures smooth and efficient height adjustments of salon chairs through foot-operated fluid power control. To achieve optimal performance and longevity, it is essential to focus not only on the hydraulic pump itself but also on the key accessories that support its functionality. In this article, as a hydraulic pump manufacturer from China, we will explore the indispensable accessories and features that enhance the reliability and efficiency of hydraulic pumps.

Classification of Hydraulic Pumps for Salon Chairs

Hydraulic pumps are categorized as follows:

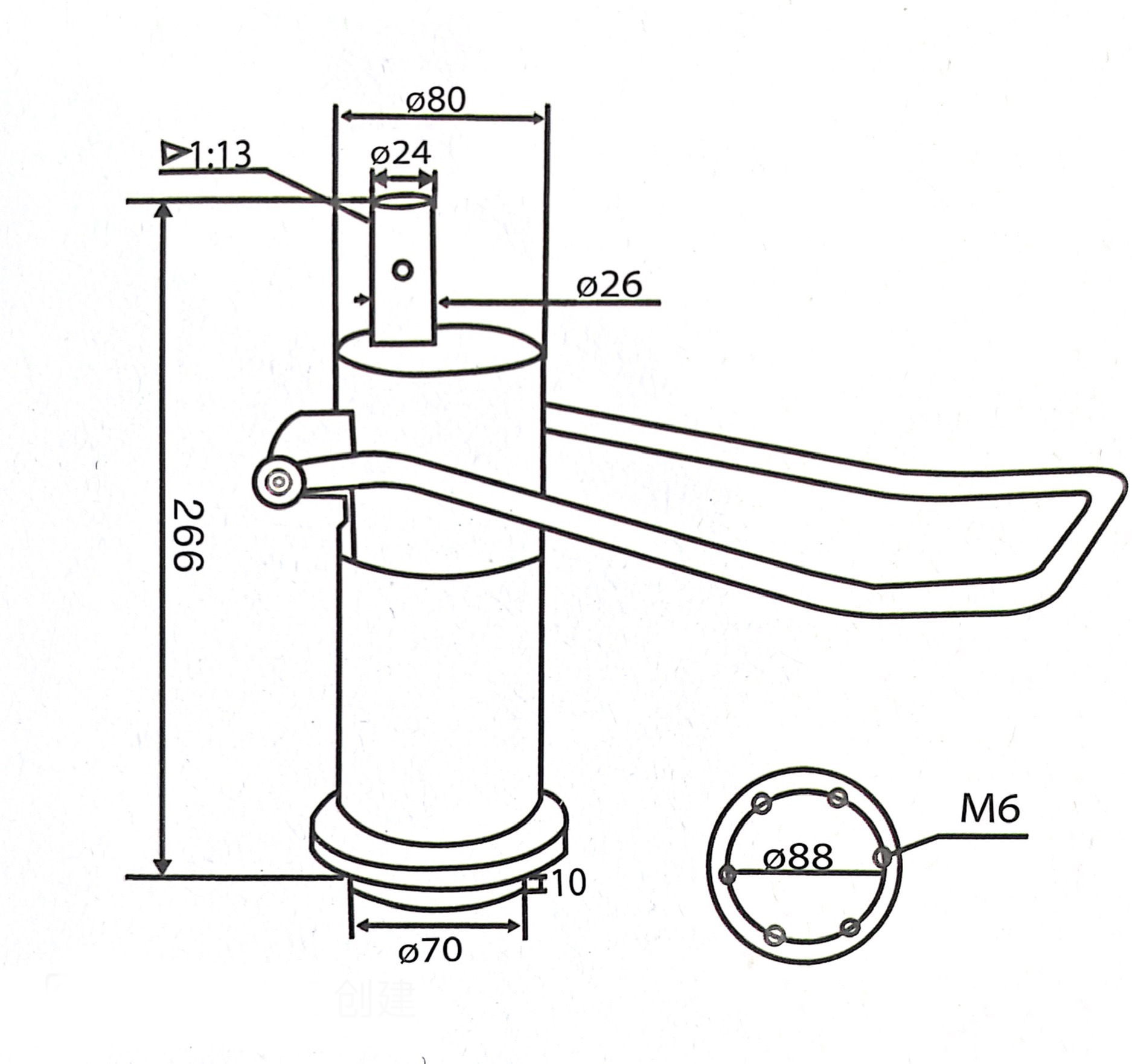

- Small Size Pumps:Suitable for salon chairs with heights ranging from 250mm-260mm, stroke lengths of 100-120mm, and pressure capacity of 200KG.

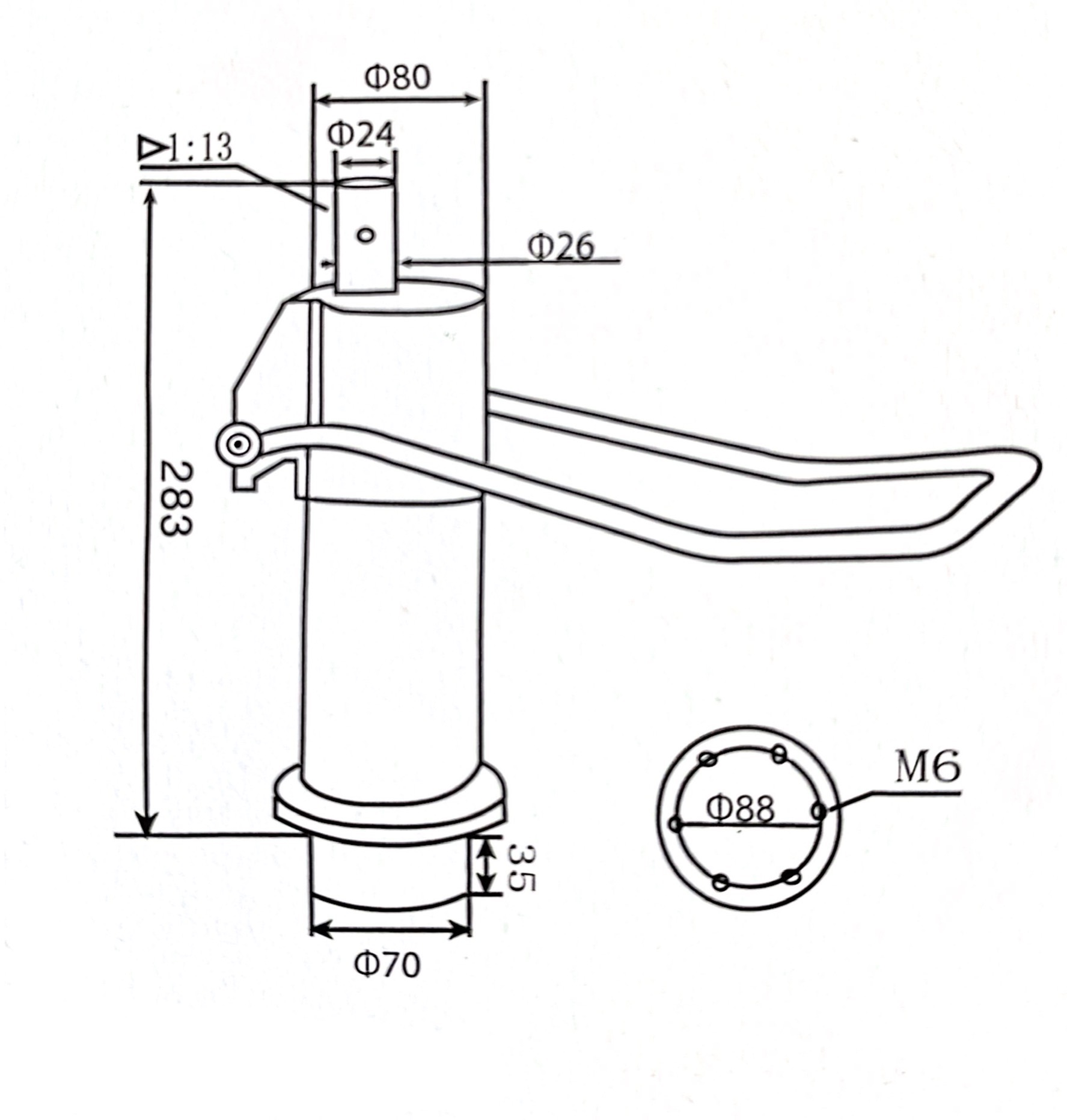

- Medium Size Pumps: Designed for styling chairs with heights between 280mm-340mm, stroke lengths of 130-140mm, and pressure capacity of 200KG.

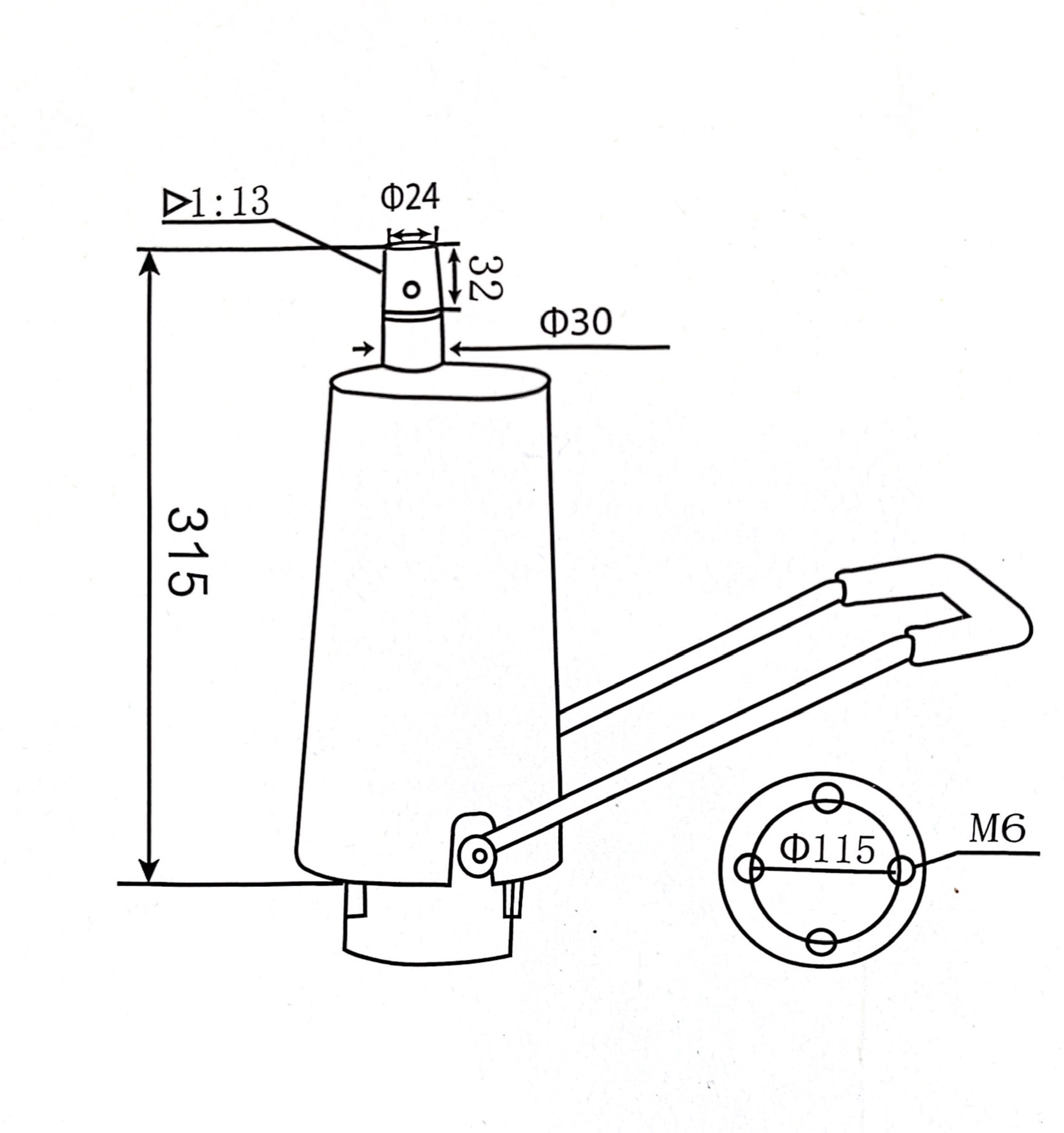

- Large Size Pumps: Used for barber reclining chairs with heights above 310mm, stroke lengths of 140mm, and pressure capacity of 200KG.

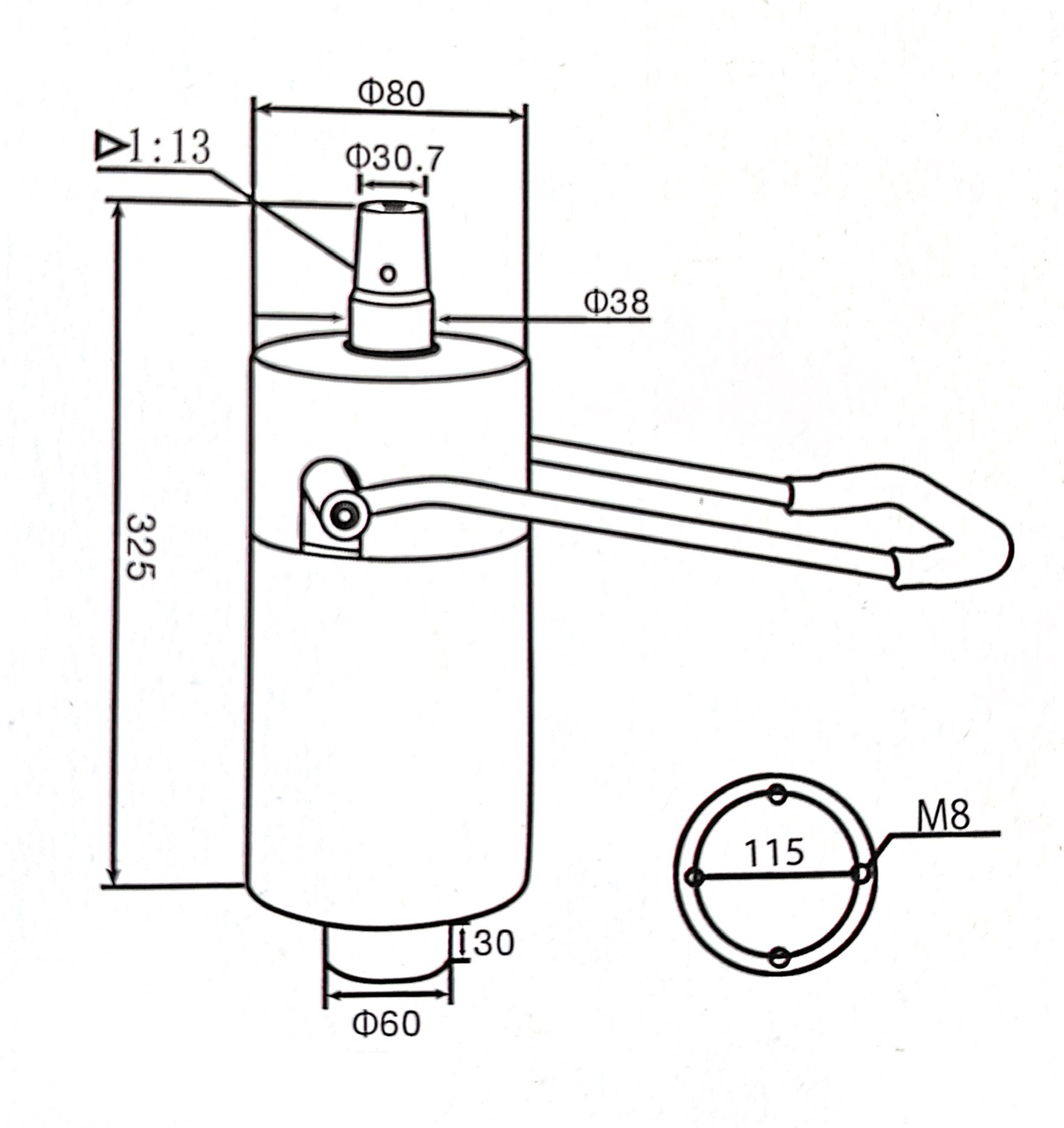

- Heavy Duty Pumps: Ideal for large barber chairs with heights over 320mm, stroke lengths of 180mm, and pressure capacity of 300KG.

These pumps are applicable to various types of chairs, including beauty chairs, haircut chairs, styling chairs, and dental chairs.

Importance of High-Quality Hydraulic Pumps for Salon Furniture

Salon furniture constitutes almost half of the investment in a beauty salon. Choosing reliable and aesthetically pleasing furniture is crucial for a successful salon. Hydraulic lift pumps play a vital role in salon furniture, directly impacting the chair’s lifespan. They convert mechanical energy into hydraulic energy, enabling precise control of the chair’s vertical movements. Ensuring the performance and reliability of hydraulic pumps is essential for maintaining the efficiency of the systems they support.

Quality Control System in Hydraulic Pump Manufacturing

Quality control is the foundation of hydraulic pump manufacturing. Adhering to international quality management standards such as ISO 9001 and 2000 ensures that each pump meets stringent quality standards. This systematic approach not only enhances pump performance but also guarantees its longevity and reliability.

Essential Accessories for Reliable Hydraulic Pumps

Seals

High-quality seals made from premium rubber or polymer materials with strict formulations and manufacturing processes offer high strength, chemical resistance, and high-temperature tolerance. These seals prevent aging, cracking, and other issues during use. Precision in size and tolerance control ensures a good fit with components, maintaining excellent sealing performance. Smooth and fine surfaces create a reliable sealing film, preventing oil leakage and premature wear. Exceptional thermal stability and aging resistance contribute to a long service life without hardening or deformation.

Manufacturing Precision of Salon Hydraulic Pumps

Our salon hydraulic oil pumps utilize fully automated mechanical cutting production processes, significantly improving manufacturing precision and ensuring product consistency and reliability. This results in smooth, noise-free operation, non-eccentric function, and a secure lifting mechanism.

Comprehensive Testing Procedures for Hydraulic Pumps

To ensure the highest quality, hydraulic pumps undergo a series of rigorous tests covering all aspects of pump performance and reliability:

- Pump Cover: Uses high-quality electroplating processes to ensure a bright, scratch-free surface.

- Oil Control: Ensures the correct oil volume in each pump.

- Pressure Maintenance: Tests the pump’s ability to maintain pressure over time.

- Vibration Testing: Checks for stability and resistance to vibrations.

- Leakage Testing: Ensures the system is free from leaks.

- Descent Speed Testing: Ensures acceptable speed and smoothness of descent.

- Locking Test: Ensures the pedal locks in the up position, preventing the chair from rotating 360 degrees.

- Fatigue Testing: Ensures long-term durability under repeated use.

Conclusion

Hydraulic pumps are essential components in salon furniture applications. Ensuring their reliability and efficiency requires attention to quality control, oil leakage prevention, and durability features. By implementing comprehensive testing procedures and key functional characteristics, WellBeauty ensure that our hydraulic pumps meet the highest standards of performance and reliability.For more information about our hydraulic pump models and their specifications, please contact us.

Hydraulic pumps are essential components in salon furniture applications. Ensuring their reliability and efficiency requires attention to quality control, oil leakage prevention, and durability features. By implementing comprehensive testing procedures and key functional characteristics, WellBeauty ensure that our hydraulic pumps meet the highest standards of performance and reliability.For more information about our hydraulic pump models and their specifications, please contact us.